Are you a metallurgy enthusiast or a professional in the field? If so, you understand the importance of having the right tools for the job. One essential tool that stands out in the world of smelting and metal casting is the 1-16kg Graphite Furnace Crucible. In this article, we will explore the features, specifications, and benefits of this exceptional melting tool. Whether you're melting gold, silver, copper, or other nonferrous metals, this crucible will undoubtedly enhance your smelting experience.

1. Introduction

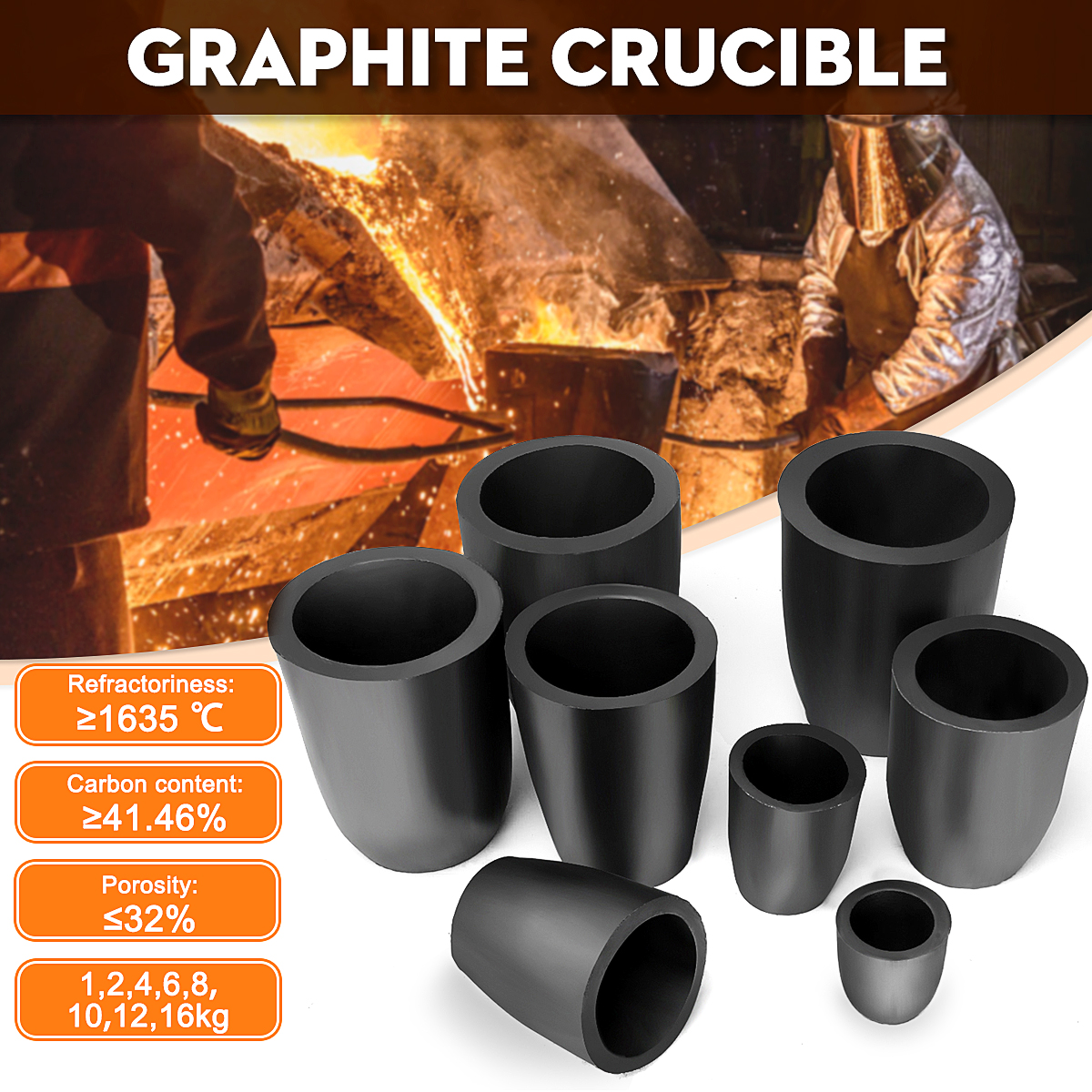

When it comes to smelting and metal casting, having a reliable and efficient crucible is crucial. The 1-16kg Graphite Furnace Crucible is designed to meet the needs of both professionals and hobbyists in the field. With its exceptional refractoriness, high thermal shock resistance, and corrosion resistance, this crucible offers outstanding performance and durability.

2. Description of the 1-16kg Graphite Furnace Crucible

The 1-16kg Graphite Furnace Casting Foundry Crucible is a specialized melting tool used in various metal casting processes. It is primarily designed for smelting alloy tool steel and nonferrous metals and their alloys. The crucible is made from high-quality graphite material, ensuring its reliability and longevity.

3. Specifications

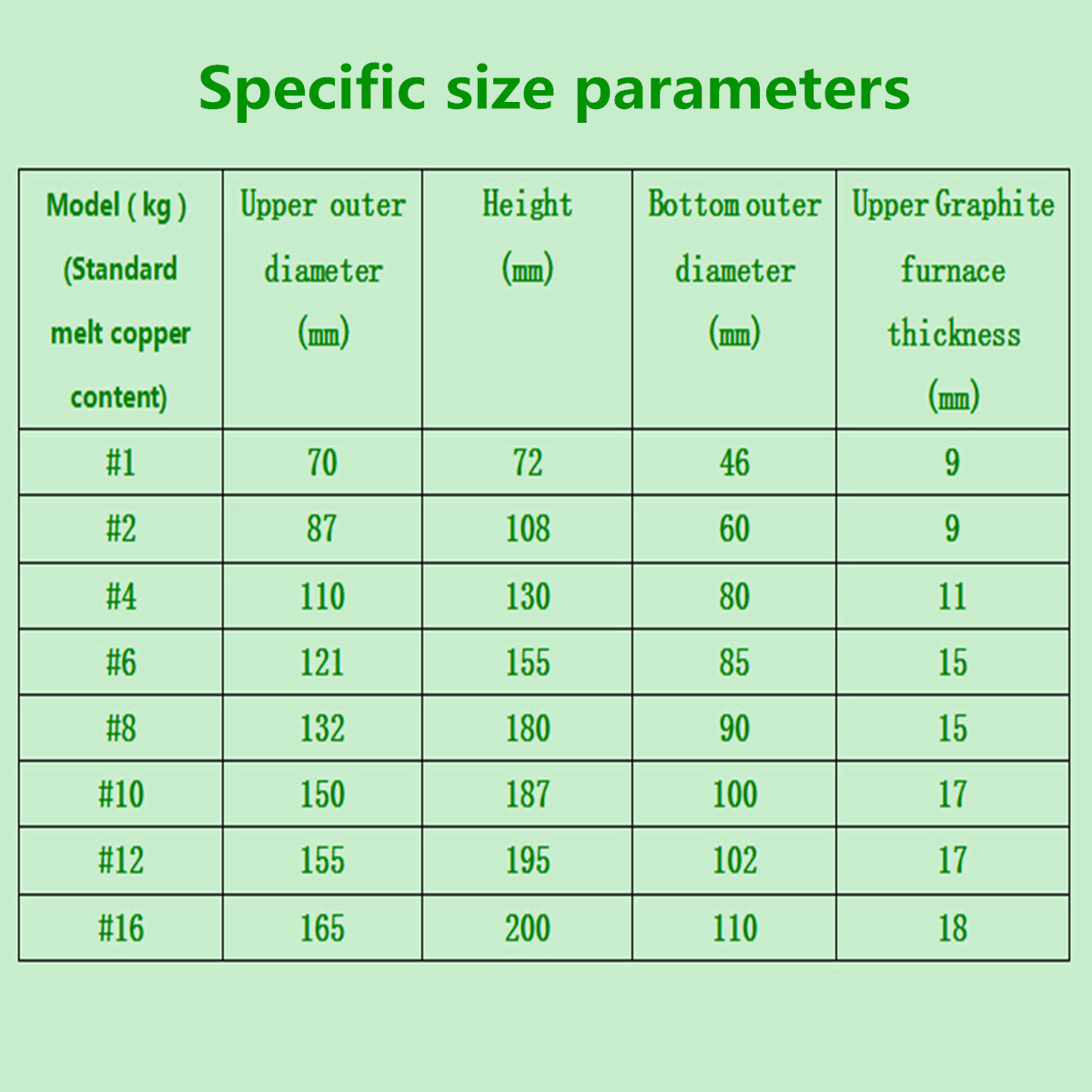

To provide you with a better understanding of the 1-16kg Graphite Furnace Crucible, let's take a look at its specifications:

Refractoriness: ≥1635 ℃

Carbon content: ≥41.46%

Porosity: ≤32%

Bulk density: ≥1.71g/cm3

Available Sizes: 1kg, 2kg, 4kg, 6kg, 8kg, 10kg, 12kg, 16kg

Quantity: 1 piece

These specifications highlight the crucible's ability to withstand high temperatures, its composition, and its density.

4. Key Features

The 1-16kg Graphite Furnace Crucible boasts several features that make it an excellent choice for smelting and metal casting:

High Density: The crucible's high density ensures that it can withstand the extreme conditions of smelting processes and maintain its structural integrity over time.

Corrosion Resistance: With its exceptional resistance to corrosion, the graphite crucible remains durable and unaffected by the chemical reactions that occur during smelting.

High Temperature Resistance: The crucible's refractoriness of ≥1635 ℃ enables it to withstand high temperatures without compromising its functionality or structural integrity.

Fast Heating and Cooling: The graphite material used in the crucible allows for rapid and efficient heating and cooling, contributing to improved smelting efficiency.

Strong Antioxidant Capacity: The crucible's composition grants it strong antioxidant properties, preventing oxidation during the smelting process.

Thermal Shock Resistance: The crucible's high thermal shock resistance ensures it can withstand rapid temperature changes without cracking or breaking

5. Utilization of the Graphite Crucible

The 1-16kg Graphite Furnace Crucible finds its application in various smelting and metal casting processes. Here are some common uses:

Alloy Tool Steel Smelting: The graphite crucible is widely used for smelting alloy tool steels. Its high refractoriness and excellent heat conductivity make it an ideal choice for this process.

Nonferrous Metal Smelting: The crucible is also suitable for melting nonferrous metals and their alloys, including gold, silver, copper, aluminum, lead, zinc, and more. It provides a reliable and efficient means of melting these materials.

Graphite Processing: Graphite crucibles are often used in the production of other graphite products. They can be utilized in processing graphite, casting crucible tanks, pull rods, molds, and other graphite components.

6. Tips for Using the Crucible

To ensure optimal performance and longevity of the 1-16kg Graphite Furnace Crucible, consider the following tips:

Storage: Store the crucible in a dry place to prevent moisture absorption. Moisture can affect the crucible's performance during smelting.

Avoid Contact with Water: After drying the crucible, avoid contact with water. Water can cause thermal shock and damage the crucible.

Handle with Care: Do not subject the crucible to mechanical impact or accidental drops, as it can lead to cracks or breakage. Handle it with caution to maintain its integrity.

7. Conclusion

The 1-16kg Graphite Furnace Crucible is an indispensable tool for smelting and metal casting processes. With its exceptional features, including high density, corrosion resistance, and high thermal shock resistance, it offers superior performance and durability. Whether you're a professional in the metallurgy field or a passionate hobbyist, this crucible provides a reliable and efficient solution for melting a wide range of materials. Invest in the 1-16kg Graphite Furnace Crucible and enhance your smelting experience today.

Frequently Asked Questions (FAQs)

1. Can the crucible be used for smelting steel?

Yes, the graphite crucible is suitable for smelting medium-carbon steel and rare metals, along with nonferrous metals.

2. How should I store the crucible when not in use?

It is recommended to store the crucible in a dry place, away from moisture and water exposure.

3. Can the crucible withstand high temperatures?

Yes, the crucible has a refractoriness of ≥1635 ℃, making it capable of withstanding high temperatures.

4. Does the package include more than one crucible?

No, the package includes one 1-16kg Graphite Furnace Crucible.

5. Is the crucible suitable for both professionals and hobbyists?

Yes, the crucible caters to the needs of professionals and hobbyists alike, offering reliable performance and durability.

10 Comment(s)

Khả năng cá cược thể thao trên FB88 rất tốt, tôi rất thích tham gia các sự kiện thể thao trực tiếp.

Mức độ bảo mật của nền tảng rất cao, khiến tôi cảm thấy an tâm hơn khi chơi.

Hệ thống bảo mật của họ rất tốt, khiến tôi hoàn toàn an tâm khi chơi.

FB88 có rất nhiều game slot, tôi luôn cảm thấy hào hứng khi chơi.

Tôi rất thích các trò chơi trên FB88, luôn có những sự kiện thú vị để tham gia.

Tôi rất thích cách họ chăm sóc người chơi, mọi vấn đề đều được giải quyết nhanh chóng.

Trường Tiểu học Nguyễn Trung Trực được thành lập năm 1985 có địa chỉ tại 9A Phạm Hồng Thái, phường Nguyễn Trung Trực, quận Ba Đình, Hà Nội (Nay thành phường Trúc Bạch). Trường hoạt động dưới sự quản lý của UBND quận Ba Đình và Phòng Giáo dục và Đào tạo Ba Đình. Trường được xây dựng khang trang trên diện tích hơn 3000 m2 với đủ các phòng học và phòng chức năng cho các hoạt động học tập, vui chơi, giải trí của học sinh.

Địa chỉ: Số 9A Phạm Hồng Thái - Ba Đình - Hà Nội

Email: [email protected]

website: https://c1nguyentrungtruc.badinh.edu.vn/

Điện thoại: 438261441

Trường Tiểu học Nguyễn Trung Trực được thành lập năm 1985 có địa chỉ tại 9A Phạm Hồng Thái, phường Nguyễn Trung Trực, quận Ba Đình, Hà Nội (Nay thành phường Trúc Bạch). Trường hoạt động dưới sự quản lý của UBND quận Ba Đình và Phòng Giáo dục và Đào tạo Ba Đình. Trường được xây dựng khang trang trên diện tích hơn 3000 m2 với đủ các phòng học và phòng chức năng cho các hoạt động học tập, vui chơi, giải trí của học sinh.

Địa chỉ: Số 9A Phạm Hồng Thái - Ba Đình - Hà Nội

Email: [email protected]

website: Https://kumu.io/NhacaiFB88betB88S/nhacaifb88betb88s#nhacaifb88betb88s

Điện thoại: 438261441

Trường Tiểu học Nguyễn Trung Trực được thành lập năm 1985 có địa chỉ tại 9A Phạm Hồng Thái, phường Nguyễn Trung Trực, quận Ba Đình, Hà Nội (Nay thành phường Trúc Bạch). Trường hoạt động dưới sự quản lý của UBND quận Ba Đình và Phòng Giáo dục và Đào tạo Ba Đình. Trường được xây dựng khang trang trên diện tích hơn 3000 m2 với đủ các phòng học và phòng chức năng cho các hoạt động học tập, vui chơi, giải trí của học sinh.

Địa chỉ: Số 9A Phạm Hồng Thái - Ba Đình - Hà Nội

Email: [email protected]

website: Https://kumu.io/NhacaiFB88betB88S/nhacaifb88betb88s#nhacaifb88betb88s

Điện thoại: 438261441

Trường Tiểu học Nguyễn Trung Trực được thành lập năm 1985 có địa chỉ tại 9A Phạm Hồng Thái, phường Nguyễn Trung Trực, quận Ba Đình, Hà Nội (Nay thành phường Trúc Bạch). Trường hoạt động dưới sự quản lý của UBND quận Ba Đình và Phòng Giáo dục và Đào tạo Ba Đình. Trường được xây dựng khang trang trên diện tích hơn 3000 m2 với đủ các phòng học và phòng chức năng cho các hoạt động học tập, vui chơi, giải trí của học sinh.

Địa chỉ: Số 9A Phạm Hồng Thái - Ba Đình - Hà Nội

Email: [email protected]

website: Https://s666s666s.com/

Điện thoại: 438261441

Trường Tiểu học Nguyễn Trung Trực được thành lập năm 1985 có địa chỉ tại 9A Phạm Hồng Thái, phường Nguyễn Trung Trực, quận Ba Đình, Hà Nội (Nay thành phường Trúc Bạch). Trường hoạt động dưới sự quản lý của UBND quận Ba Đình và Phòng Giáo dục và Đào tạo Ba Đình. Trường được xây dựng khang trang trên diện tích hơn 3000 m2 với đủ các phòng học và phòng chức năng cho các hoạt động học tập, vui chơi, giải trí của học sinh.

Địa chỉ: Số 9A Phạm Hồng Thái - Ba Đình - Hà Nội

Email: [email protected]

website: Https://s666s666s.com/

Điện thoại: 438261441

Trường Tiểu học Nguyễn Trung Trực được thành lập năm 1985 có địa chỉ tại 9A Phạm Hồng Thái, phường Nguyễn Trung Trực, quận Ba Đình, Hà Nội (Nay thành phường Trúc Bạch). Trường hoạt động dưới sự quản lý của UBND quận Ba Đình và Phòng Giáo dục và Đào tạo Ba Đình. Trường được xây dựng khang trang trên diện tích hơn 3000 m2 với đủ các phòng học và phòng chức năng cho các hoạt động học tập, vui chơi, giải trí của học sinh.

Địa chỉ: Số 9A Phạm Hồng Thái - Ba Đình - Hà Nội

Email: [email protected]

website: Https://s666s666s.com/

Điện thoại: 438261441

Trường Tiểu học Nguyễn Trung Trực được thành lập năm 1985 có địa chỉ tại 9A Phạm Hồng Thái, phường Nguyễn Trung Trực, quận Ba Đình, Hà Nội (Nay thành phường Trúc Bạch). Trường hoạt động dưới sự quản lý của UBND quận Ba Đình và Phòng Giáo dục và Đào tạo Ba Đình. Trường được xây dựng khang trang trên diện tích hơn 3000 m2 với đủ các phòng học và phòng chức năng cho các hoạt động học tập, vui chơi, giải trí của học sinh.

Địa chỉ: Số 9A Phạm Hồng Thái - Ba Đình - Hà Nội

Email: [email protected]

website: Https://s666s666s.com/

Điện thoại: 438261441

Loved the clarity here. A quick but valuable read.

Leave a Comment